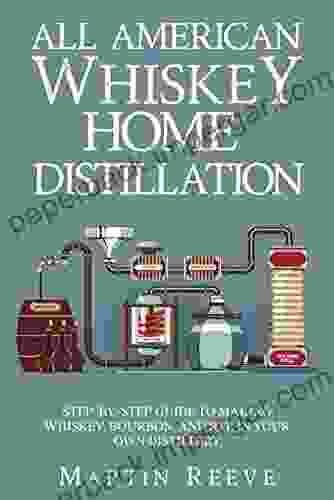

Step-by-Step Guide to Making Whiskey, Bourbon, and Rye in Your Own Distillery

4.4 out of 5

| Language | : | English |

| File size | : | 5249 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 105 pages |

| Lending | : | Enabled |

Distilling your own spirits at home is a rewarding experience that can produce high-quality, flavorful beverages. Whether you're a seasoned distiller or just starting out, this guide will provide you with the comprehensive knowledge and step-by-step instructions you need to create your own whiskey, bourbon, or rye in the comfort of your own distillery.

This guide covers all aspects of the distilling process, from selecting and preparing your ingredients to aging and bottling your finished product. We'll also provide you with tips and tricks to help you troubleshoot common problems and ensure that your whiskey, bourbon, or rye turns out perfect every time.

Selecting Your Ingredients

The first step in making whiskey, bourbon, or rye is to select your ingredients. The most important ingredient is, of course, the grain. You can use any type of grain to make whiskey, but the most common grains are corn, rye, and wheat.

The type of grain you use will determine the flavor of your whiskey. Corn whiskey has a sweet, smooth flavor, while rye whiskey has a spicy, peppery flavor. Wheat whiskey is known for its mild, slightly fruity flavor.

In addition to grain, you will also need water, yeast, and enzymes. Water is used to dissolve the sugars in the grain and to create the mash. Yeast is used to ferment the mash and convert the sugars into alcohol. Enzymes are used to break down the starches in the grain into sugars.

Preparing Your Ingredients

Once you have selected your ingredients, you need to prepare them for the distilling process.

The first step is to grind the grain. You can use a grain mill or a food processor to grind the grain into a coarse powder.

Next, you need to mash the grain. Mashing is the process of adding water to the grain and heating it to a specific temperature. This allows the enzymes to break down the starches in the grain into sugars.

The mash should be held at a specific temperature for a period of time, typically 1-2 hours. After the mashing process is complete, you can lauter the mash. Lautering is the process of separating the liquid from the solids in the mash.

The liquid, which is now called wort, is ready to be fermented.

Fermenting the Wort

Fermentation is the process of converting the sugars in the wort into alcohol. This process is carried out by yeast.

To ferment the wort, you will need to add yeast to the wort and allow it to ferment at a specific temperature for a period of time, typically 3-7 days.

During fermentation, the yeast will convert the sugars in the wort into alcohol and carbon dioxide. The carbon dioxide will escape from the wort, and the alcohol will remain.

Distilling the Wash

After the fermentation process is complete, the wort is now called wash. The wash is ready to be distilled.

Distillation is the process of separating the alcohol from the water in the wash. This process is carried out by heating the wash and condensing the vapors.

The vapors are then collected and condensed into a liquid. This liquid is now called distillate.

The distillate is typically distilled a second time to produce a higher-proof spirit.

Aging the Whiskey

After the distilling process is complete, the whiskey is ready to be aged. Aging is the process of storing the whiskey in barrels for a period of time.

During aging, the whiskey will interact with the wood of the barrels and develop a complex flavor profile.

The type of wood used for the barrels will affect the flavor of the whiskey. Oak is the most common type of wood used for aging whiskey, but other types of wood, such as cherry, maple, and walnut, can also be used.

The length of time that the whiskey is aged will also affect its flavor. Whiskey that is aged for a shorter period of time will have a lighter flavor, while whiskey that is aged for a longer period of time will have a deeper, more complex flavor.

Bottling the Whiskey

Once the whiskey has been aged, it is ready to be bottled.

To bottle the whiskey, you will need to fill bottles with the whiskey and then seal the bottles with corks or caps.

The whiskey is now ready to be enjoyed!

Making whiskey, bourbon, or rye at home is a rewarding experience that can produce high-quality, flavorful beverages.

By following the steps outlined in this guide, you can create your own unique spirits that you can enjoy with friends and family.

So what are you waiting for? Start distilling today!

4.4 out of 5

| Language | : | English |

| File size | : | 5249 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 105 pages |

| Lending | : | Enabled |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Ross NelsonWritings Papers Reviews Articles Short Shorts Thoughts: The Ultimate Resource...

Ross NelsonWritings Papers Reviews Articles Short Shorts Thoughts: The Ultimate Resource... Ralph TurnerFollow ·17k

Ralph TurnerFollow ·17k Chase MorrisFollow ·10.8k

Chase MorrisFollow ·10.8k Leo TolstoyFollow ·15k

Leo TolstoyFollow ·15k Jared PowellFollow ·18k

Jared PowellFollow ·18k Cooper BellFollow ·8k

Cooper BellFollow ·8k Banana YoshimotoFollow ·17.9k

Banana YoshimotoFollow ·17.9k Kevin TurnerFollow ·9.9k

Kevin TurnerFollow ·9.9k Melvin BlairFollow ·14.4k

Melvin BlairFollow ·14.4k

Jeffery Bell

Jeffery BellUnlock the Complexities of American Indian Law with...

Welcome to the...

Louis Hayes

Louis HayesMaster Street Photography: The Ultimate Beginner's Guide

Are you ready to...

Don Coleman

Don ColemanUnlock Your Business Potential: A Comprehensive Guide to...

Embark on a transformative journey with...

Ruben Cox

Ruben CoxComparative Guide to International Competition Law: A...

` In today's interconnected global...

Hamilton Bell

Hamilton BellElevate Your Bread-Making Skills: Unleash the Secrets of...

The Ultimate Guide for Novice Bakers to...

4.4 out of 5

| Language | : | English |

| File size | : | 5249 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 105 pages |

| Lending | : | Enabled |